Heinrich Christian Eisenbrandt

Importer and Manufacturer

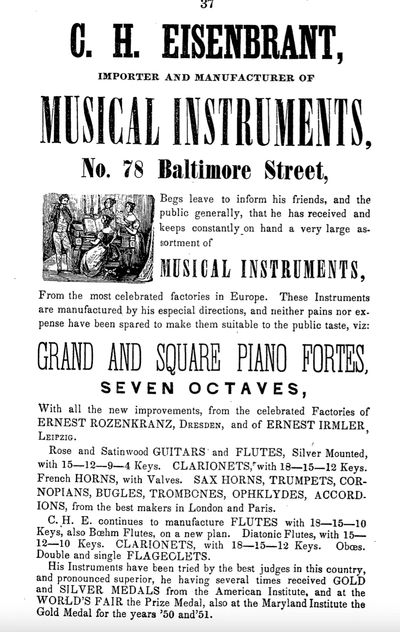

Heinrich was born in Goettingen, Germany and moved to Philadelphia in 1811 and finally to Baltimore in 1819. A large number of the American fifers during the War of 1812, were equipped with Eisenbrandt Fifes. He returned to Germany in 1816 and worked in the family business, winning an appointment as the ‘court instrument maker in Hannover. He returned to Baltimore in 1819 where he opened a factory and was very successful. He also married Mary C. (Spilker) on May 1, 1845 in Baltimore. His factory produced clarinets, fifes, drums, basset-horns, bassoons, oboes, flutes, flagolets (member of the flute family) and brass instruments. He was praised for technical innovations in the valves of the saxhorn, and owned two patents used for brass instruments. He also invented a method of drilling fife bores in one step, whereas his competitors used multiple steps. This allowed him to underbid his competition (American Fife makers around the time of the War of 1812). It is also reported that he was the first woodwind maker to use rosewood instead of the standard boxwood at least 10-15 years before other instrument makers began using the hardwood. His factory was located at 78 W. Baltimore Street and 39 S. Broadway.

His son, H.W.R. Eisenbrandt, born in Baltimore in 1834, continued the family business, which lasted until 1949. H.R. Eisenbrant became H.R. Eisenbrandt and Sons, Inc., and were located at 306-308 N. Howard Street. H.R. Eisenbrandt lived in the Springlake area of Baltimore. He married Jeannetta, from Prussia and together they had W. Albert, C. Henry (1860), Frederick (1862), Charles, Edward, Jeannette, Rosalina and Herman. Several of the sons also made musical instruments. Henry and Albert were twins.

Sources: Colonial Williamsburg Mobile; History of the Ancients, Worldpress; 1880 U.S. Federal Census records, Maryland Archives [Maryland Marriages].

15 3/16" diameter by 10 1/4" tall.

This solid maple shell is secured with widely spaced copper tacks, and has only a wooden vent insert for decoration.

Probably the most unique aspect of this drum is the sheet of copper tacked to the upper bearing edge. You can clearly see the divots made in the copper from beating on it with sticks.

The wonderful label is pasted inside the drum shell which simply reads, "C. H. EISENBRANDT/ BALTIMORE."

This image also provides a wonderful view of the circular shaped saw marks left from cutting this piece from the felled log.

16 ½” diameter by 14” tall.

This drum carries the label of C.H. Eisenbrandt of Baltimore. On the shell of the drum is a painted motif the includes an eagle in flight above an American shied and red ribbon fluttering in the wind.

The red painted counter hoops are drilled for ten holes, and what appears to be newer rope is tensioned with riveted leather braces. I have seen this style of brace on other drums, but I do not think it was the main method of utilized in the 19th century.

Six strands of natural gut lay across the bottom skin and exit between the counter hoop and flesh hoop, where a brass tensioner holds them in place.

16" diameter by 13 1/4" tall.

The maple shell is secured with two vertical rows of brass tacks, and a five-pointed star is formed around the vent made of brass tacks as well.

The drum and counter hoops look fairly well used, and the latter exhibit some cracking along the edge of the scarf joint.

Both skins look to be quite old as well, possibly original to the drum's construction. The counter hoops are drilled for eight holes.

A close-up of the label reads, "H.R. EISENBRANDT/ 78 WEST BALTIMORE/ BALTIMORE, MD./

Henry Raphael Eisenbrandt began working with his father in 1856, and appears to have taken over the family business sometime in the late 1860s.

Eisenbrandt's label is quite fanciful with the harp and music scroll at the center.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.